Facial masks are an essential part of skin beauty for modern women, and the production and processing of facial masks provide us with a variety of facial mask products. The job of facial mask production and processing is to make facial masks from various materials and ingredients, and ensure the quality and safety of the products so that consumers can use them with confidence. In this article, we will discuss the workflow and production process of facial mask production and processing.

一. Work flow of facial mask production and processing

The workflow of facial mask production and processing includes material procurement, production, quality inspection and packaging for shipment.

1. Material procurement: Facial mask production and processing requires the purchase of various facial mask making materials, including paper masks, water, essence, preservatives, etc. When purchasing, you need to pay attention to the quality of the product and the reputation of the supplier to ensure the quality and safety of the facial mask produced.

2. Production: After purchasing enough materials, the mask production and processing begins. The process involves mixing various materials together, heating, cooling, filling, and more. During the production process, product standards and procedures must be strictly followed to ensure product quality and safety.

3. Quality inspection: After the production is completed, the mask production and processing needs to conduct quality inspection of the product. This process includes inspection of the product’s appearance, materials, ingredients, performance, etc. to ensure that the product meets specifications and standards.

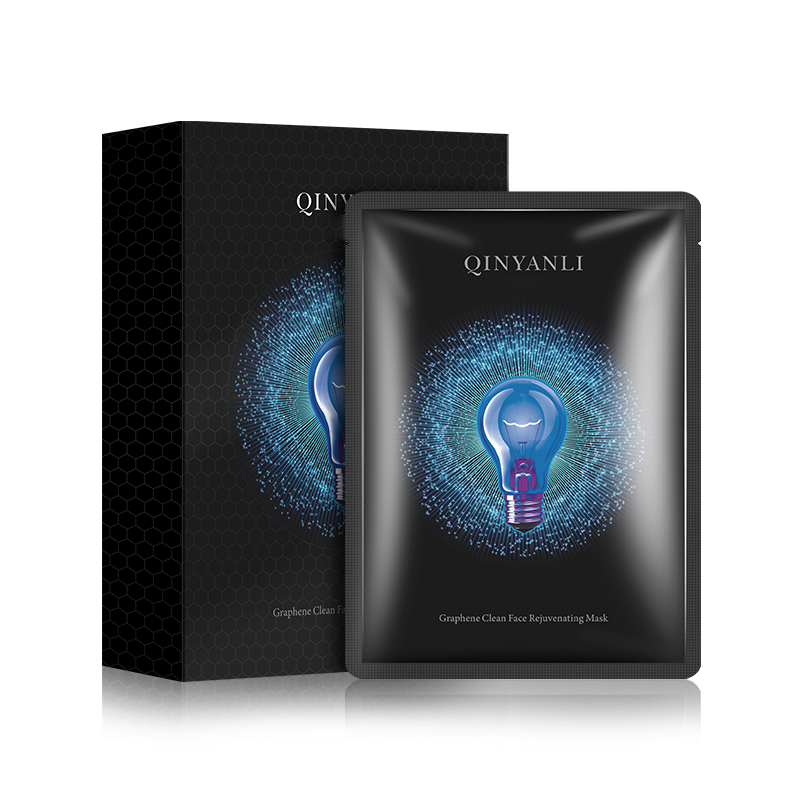

4. Packaging and shipping: After quality inspection, the facial mask production and processing company will package the products and then ship them to sales channels or sell them directly to consumers.

二. Mask making process

The making process of facial mask mainly includes the following steps:

1. Paper mask production: The production and processing of facial masks requires the production of paper masks. The paper mask is the carrier of the mask and can cover the essence evenly on the skin. The paper film can be made of cotton, non-woven fabric, collagen, etc.

2. Essence preparation: Essence is the component of the facial mask. The production and processing of facial masks require the production of different essences according to different needs and formulas. The ingredients of essence can be vitamin C, hyaluronic acid, collagen, etc.

3. Soak the paper mask: Soak the prepared paper mask in the essence, so that the paper film can fully absorb the essence.

4. Packaging: Pack the soaked paper film, usually in small bags one by one, for the convenience of consumers to use and carry.

Post time: Nov-14-2023